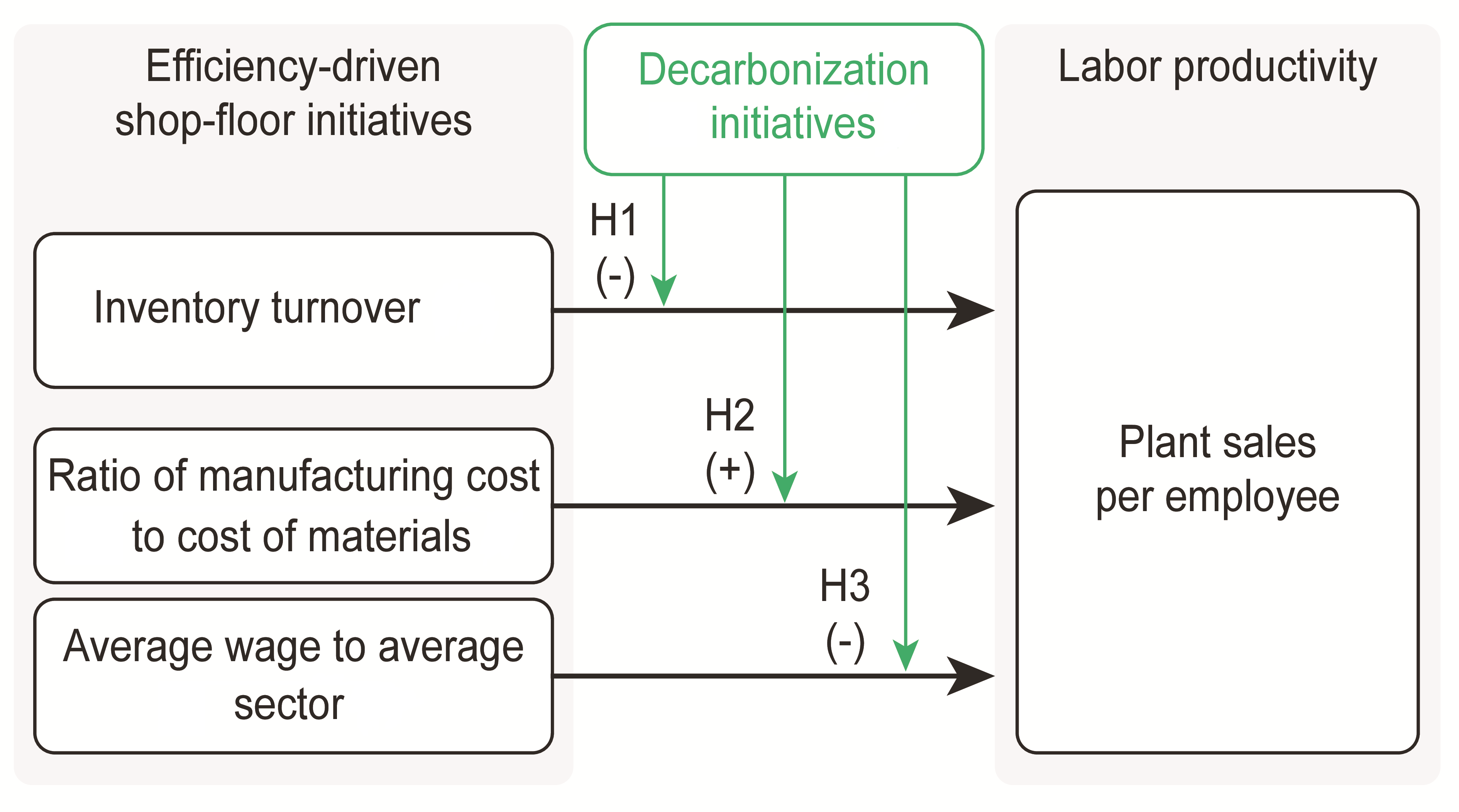

In a recent paper, we show how decarbonisation in industrial plants interacts with efficiency-driven initiatives regarding flow management, waste reduction and workforce commitment, which represent three key fields in which high-performance shop floors strive. Inventory turnover reflects our measure for improvements in flow. The ratio of the total manufacturing cost to the cost of materials indicates how efficiently firms carry out their processes. The average wage to the average sector wage gives insight on the degree of firm commitment to employees (Figure 1). Decarbonisation is measured as CO2 emissions (tons) divided by value added. Finally, plant sales per employee is our proxy for plant performance. We use a unique dynamic panel data covering nine years and including information for 988 manufacturing plants. These data draw from two official registers to which companies are legally required to offer truthful information: the Spanish Business Register (SBR) and the European Pollutant Release and Transfer Register (E-PRTR).

Figure 1. Expected moderating effect of decarbonisation on the association between efficiency initiatives and productivity

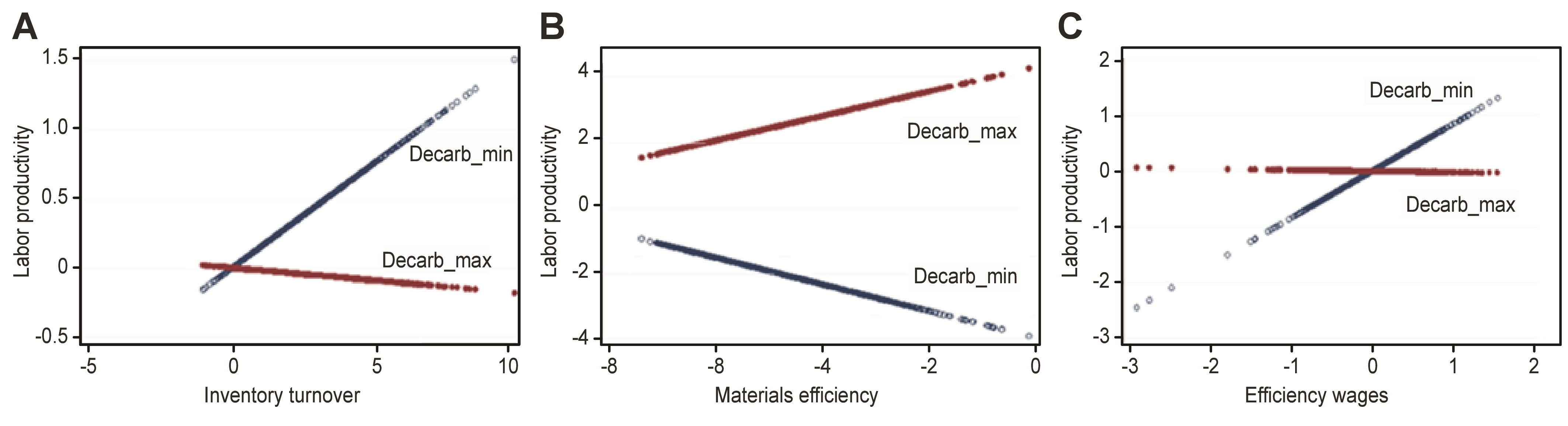

Our results suggest that initiatives to improve materials efficiency may have a greater positive impact on labour productivity when conducted together with efforts to decarbonise. The opposite holds, however, for initiatives that target inventory turnover and efficiency wages. Decarbonisation requirements could thus conflict with the design of pulled flows to the extent that they may even eliminate the positive influence of inventory turnover on labour productivity. A similar situation occurs with policies linked to efficiency wages because when workers are expected to meet “decarbonisation requirements” in high-performance shop floors – which are themselves very demanding – they gradually reduce their positive impact on labour productivity. Figure 2 illustrates the aggregate impact – the direct effect plus moderation – of each of the efficiency-driven shop-floor initiatives on labour productivity under two possible extreme (maximum and minimum) decarbonisation scenarios.

Figure 2. Impact of efficiency-driven initiatives on labour productivity under two possible extreme decarbonisation scenarios

The global impact of inventory turnover on labour productivity is positive for firms with very low degrees of decarbonisation (Decarb_min, blue curve) and is reduced to almost zero as the firm increases its decarbonisation achievements (Decarb_max, red curve: Figure 2A). This inelastic behaviour suggests that under extreme low-carbon conditions in which decarbonisation is an absolute priority, the positive impact of inventory turnover on labour productivity may be practically cancelled due to the intense decarbonisation requirements. Here, the “green-oriented requirements” associated with decarbonisation (e.g., higher cycle times and changeover processes, more audits, and energy controls) normally demand additional work, which could negatively affect labour productivity.

A similar situation can be found when we analyse the policies associated with above-sector wages. The impact on labour productivity will be greater in plants with a low degree of decarbonisation (Decarb_min, blue curve). On the other hand, when the shop floor has high-decarbonisation conditions, this positive impact of higher-efficiency wages on labour productivity may even be cancelled out (Figure 2C). This inelastic behaviour reflects the trade-off described above: when a performance-oriented worker is required to take care of carbon intensity in the job at hand, the possible conflict among multiple objectives (not always compatible) will end up decreasing global efficiency.

Our results provide a different picture when we analyse material efficiency. Its impact on labour productivity is positive (and very intense) for firms with low carbon intensity (Decarb_max, red curve), although it is necessary to reach a minimum degree of decarbonisation for this positive effect to occur. Hence, while the “basic” steps of decarbonisation (e.g., life cycle assessment, cradle to cradle analysis, energy audits or the adoption of cleaner technologies) consume only technical and human resources that would otherwise go to improvement initiatives, the positive influence of decarbonisation improves once the necessary level of maturity has been achieved. This phenomenon enhances the impact of material efficiency on performance, which becomes increasingly significant as the practices to improve materials efficiency become more intense (e.g., value stream mapping, quality circles, and Kaizen workshops).

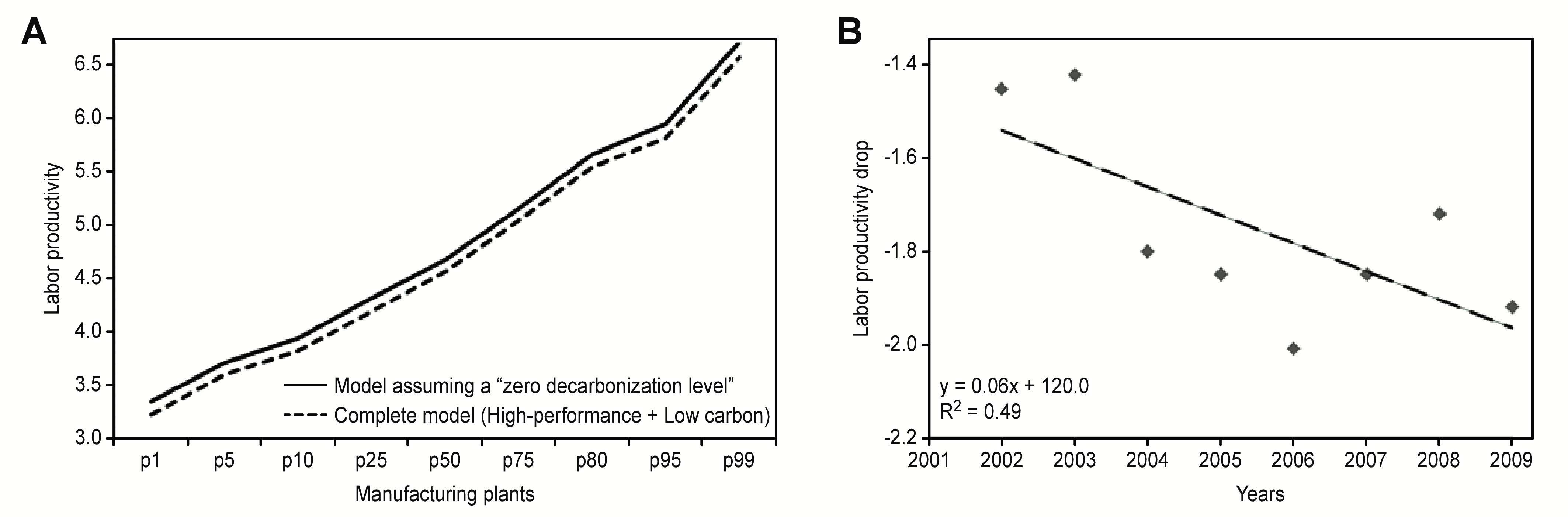

In summary, decarbonisation improves the impact of efficiency-driven shop-floor initiatives associated with materials efficiency but damages the effect of inventory turnover and efficiency wages. To provide further insights into this issue, Figure 3 analyses the impact on plant labour productivity when low-carbon initiatives are introduced in a strictly high-performance environment, i.e., one in which we assume an initial “zero decarbonisation level”. Our results indicate that a company that invests in low-carbon initiatives can expect to suffer a 1.8% decrease in labour productivity. Considering the average labour productivity of our sample (362.8 k€/employee) and its average size (204 employees), these results yield an average loss of 1.33 M€ per company per year. Thus, from an economic point of view, decarbonisation reduces the output level with respect to that of strictly high-performance conditions. This evidence therefore suggests that climate change goals impacting industrial firms might be difficult to accomplish if managers expect to achieve decarbonisation for free with current organisational best practices. Decarbonisation projects could therefore be at risk.

Figure 3. Effect of low-carbon initiatives in a high-performance environment

♣♣♣

- This blog post is based on the authors’ paper From efficiency‐driven to low‐carbon operations management: Implications for labor productivity, Journal of Operations Management, early view.

- The post gives the views of its author(s), not the position of LSE Business Review or the London School of Economics.

- Featured image by trapezemike, under a Pixabay licence

- When you leave a comment, you’re agreeing to our Comment Policy

Antonio Sartal is currently distinguished researcher at the University of Vigo, Spain. His research agenda addresses the intersection of operational excellence, climate change and technological challenges. He has published his work in leading academic journals.

Antonio Sartal is currently distinguished researcher at the University of Vigo, Spain. His research agenda addresses the intersection of operational excellence, climate change and technological challenges. He has published his work in leading academic journals.

Miguel Rodríguez is assistant professor at the University of Vigo. Circular Economy is the centrepiece of his research, showing the main drivers of circular economy indicators (e.g. water, biomass, other materials and energy), and following an interdisciplinary view devoted to decoupling economic growth and environmental impacts. Also, providing a critical view on usual but deficient “efficiency” indicators (intensity, productivity) and designing new approaches for measuring efficiency and circularity achievements.

Miguel Rodríguez is assistant professor at the University of Vigo. Circular Economy is the centrepiece of his research, showing the main drivers of circular economy indicators (e.g. water, biomass, other materials and energy), and following an interdisciplinary view devoted to decoupling economic growth and environmental impacts. Also, providing a critical view on usual but deficient “efficiency” indicators (intensity, productivity) and designing new approaches for measuring efficiency and circularity achievements.

Xosé H. Vázquez is currently full professor of management at the University of Vigo, Spain. His research agenda lies at the intersection of strategy, industrial operations and climate change. His work has targeted diverse audiences in the field of economics, business, management and industrial engineering through leading academic outlets.

Xosé H. Vázquez is currently full professor of management at the University of Vigo, Spain. His research agenda lies at the intersection of strategy, industrial operations and climate change. His work has targeted diverse audiences in the field of economics, business, management and industrial engineering through leading academic outlets.